I kick-started the evening by beginning a group discussion about what people from different backgrounds would like to see in a series of formal 3D print-courses to be run by #3DPM@MadLab. We got some great feedback, and these will be presented soon for members and non-members of the group from anywhere to attend. Details will follow, so keep checking the blog and the MadLab site!

Keith and Mark started to discuss aspects of basic and advanced 3D printing to the assembled masses of newbies and not-so-newbies. Everyone seemed rapt, and everyone seemed to have learnt something new! I know I did! There's still so much information going around, that everyones doing their best to soak it up. It's important to us that we get as much as possible into the first iteration of the #3DPM 3D printing course.

MadLab will soon be opening a store to support the sales of various accoutrements related to the various groups that make it their home. Rachael from MadLab asked us to be part of the 3D printing offerings they're considering hosting, in collaboration with the 3D print guys at HackSpace. We're going to eventually offer a place to buy 3D printers, consumables, and come for consultancy and expertise care of #3DPM. Watch this space for when we go live!

So far so good, we're building courses to get the message and skills out there, and we're organising a physical presence to cement 3D printing in Manchester. The only one we know of outside of London! So what are we doing with #3DPM? The group has matured in the space of four meetings at MDDA and MadLab (see our previous blog posts!).

From now on in, we'll be asking all attendees to bring along a laptop with a downloaded and installed version of Google Sketch-up (other dl sites are available other than the link!). #3DPM is supporting this as we know we've got in-house advice and experience to give on this software. You're free to use any other 3D modelling software, but we can't guarantee that there will be expertise to help you in advance. This will change as time goes by, as we're looking to expand on this!

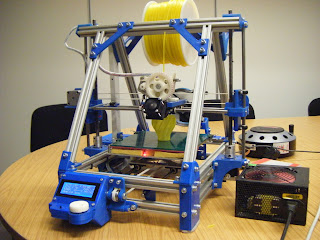

0g~~60_35.JPG) |

| Wrought iron signs used to be ubiquitous - perhaps 3D printed signs will take their place? |

The whole point of getting people to bring a Sketch-up loaded laptop, is that we're enthusiastic about giving members the chance to work on their own designs, or the #3DPM group project of a 3D printed art installation that will join, at roof-top level, MadLab to Holden & Sons building (opposite each other on Edge Street, Manchester). The art installation was inspired through a chat between myself and Peter, and my memory of wrought iron signs across the north of England. Wrought iron signs were more than just a device for communication, with aesthetic design cues, the signs would project what these companies stood for and what they could manufacture for you. #3DPM will get all interested group members to contribute towards a 3D printed art-installation that will cement our area in Manchester, as the birth-place of a manufacturing revolution.

We've so much going on now, and we're always looking for people to volunteer their skills, or just come along and see whats going on. All are welcome, and we're here to get everyone involved, so see you at the next meeting on the 12th of August at MadLab!